Consulting

Affordable Yearly consulting packages & Extended R&D services available

Affordable Yearly consulting packages & Extended R&D services available

We offer Flagship - Yearly consulting packages available for Offsite/Onsite regular consultation, Extended R&D services and Value Engineering solution.

EXANS Technologies partner with clients to implement Value engineering by enabling them to improvise Product Development, by cost cutting and reducing time to develop a Product.

EXANS Technologies have helped many clients solve a variety of Industry based problems. Our Industry based Consulting services encompass a very wide range of Industries. The most common Industries that EXANS Technologies carries out are shown below:

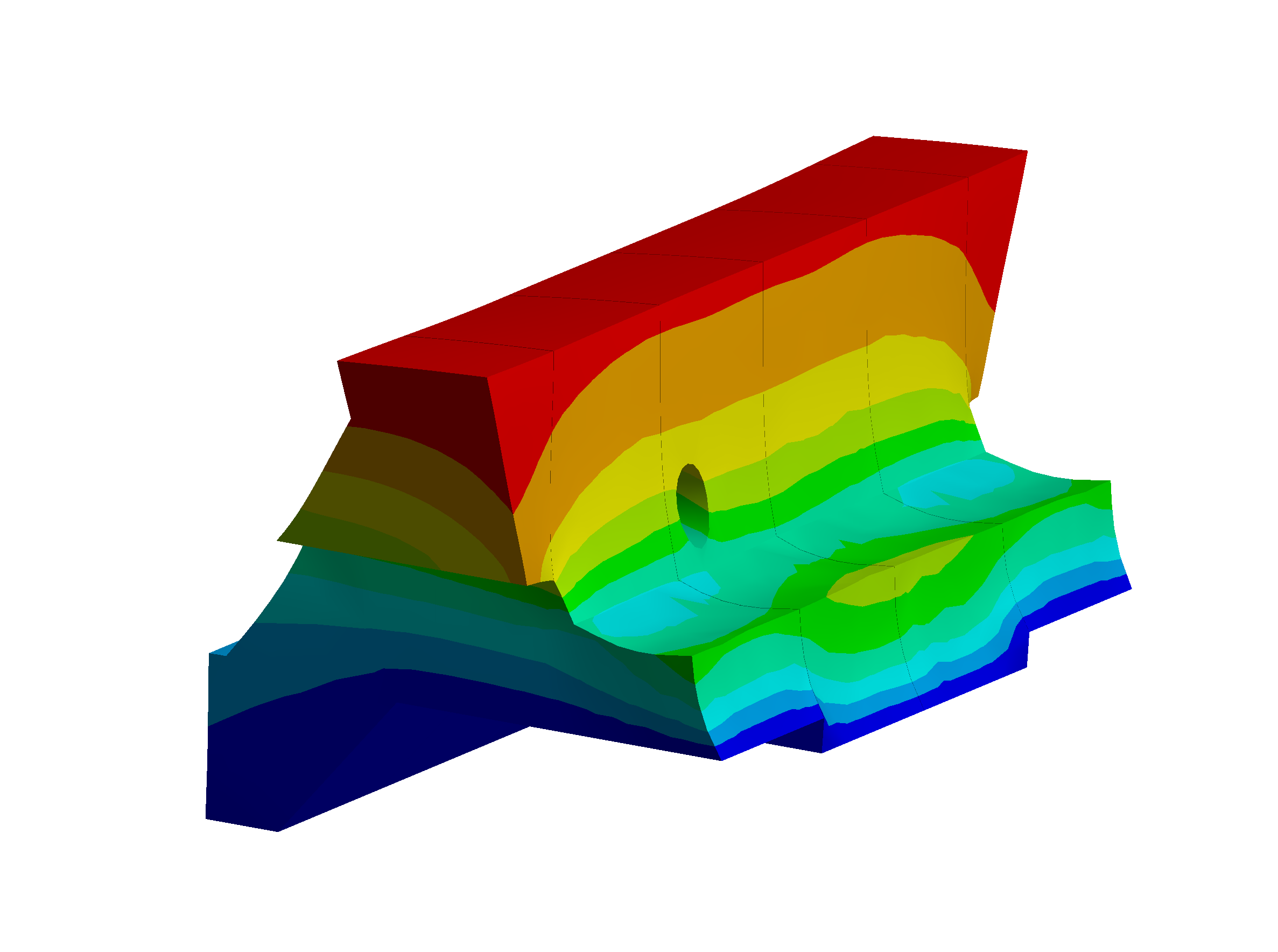

Your products are complex, and how they will be used in the real world is complicated. In order to effectively use virtual prototyping to answer your product development questions you need a partner that can model a very broad set of situations. Many smaller or specialized simulation outsourcing companies will modify the problem statement to fit the tools and experience they have. EXANS Technologies wide range of capabilities allows us to really apply the right tools to each problem, providing the most cost effective and accurate solution available.

The most common types of simulation that EXANS Technologies carries out for our customers are shown below: